Transform or fail.

If you don’t get there first, your competition will.

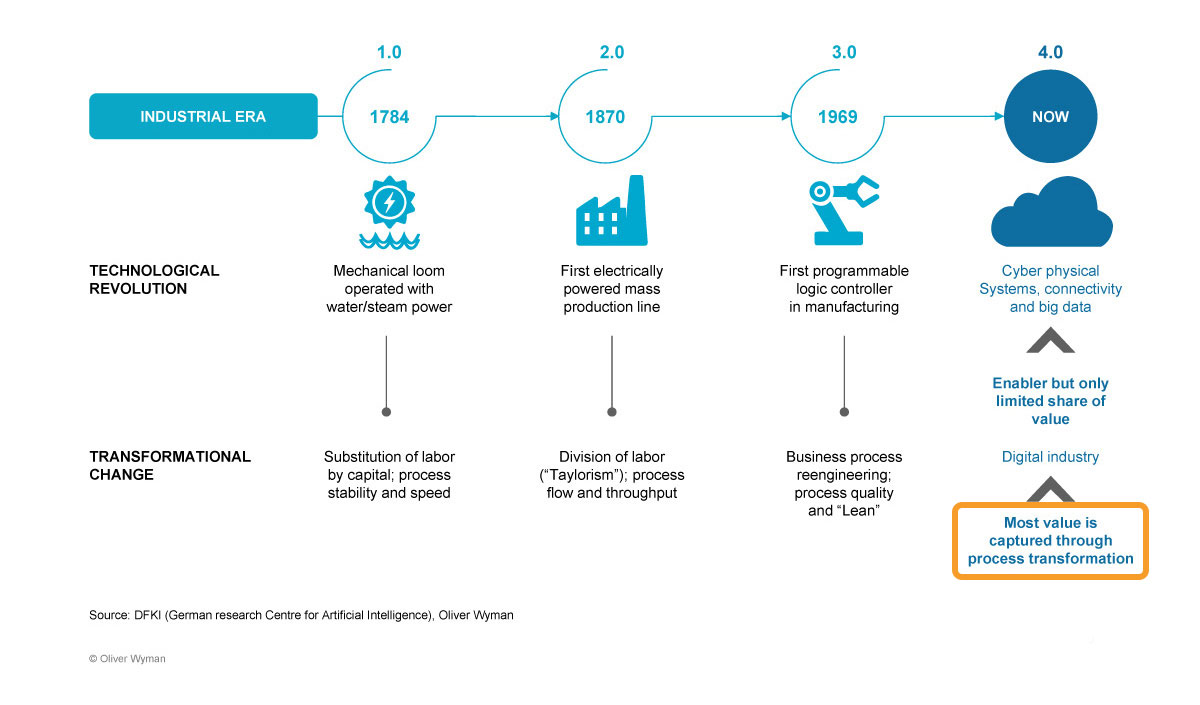

The confluence of seven powerful technologies has launched a new Industrial Age.

1. Cloud Computing/Big Data

Instantly scalable computational power and data storage paired with sophisticated applications and analytics on demand from third party providers (AWS, Google, Microsoft, IBM) can store an unlimited amount of data, which can be accessed in real time from anyplace on the globe. These capabilities let a company evaluate all aspects of its business: customer interactions, preferences, choices, failure rates of machines, etc. A key difference is that instead of analyzing a finite set of data because of limitations on storage and computation, businesses can now analyze the entire data set, which makes the inferences and conclusions much more powerful and useful rather than approximating/guessing from a much smaller sample size.

2. Artificial Intelligence

Provides the ability to analyze Big Data, to discover patterns that a human could not see alone and to implement revolutionary processes with greater accuracy, more rapid response times and lower costs.

The value of AI and machine learning to data analytics can be distilled into three separate value propositions: speed, scale, and convenience. There is simply far too much valuable customer data to be collected, processed and turned into insights for any company to remain competitive without making full use of modern analytics tools.

3. Internet of Things

Lets the knowledge derived from the previous technologies interact with people and equipment to provide alerts, adjustments to systems, and information in real time.

In addition to bringing us all faster broadband speeds and more reliable mobile networks, the proliferation of 5G will also accelerate advancements in smart city, smart vehicle, smart manufacturing, and scores of IoT-intensive technologies.

4. WiFi

WiFi 6 download speeds are up to 3x faster than were achievable with WiFi 5, with faster data speeds to far more devices than WiFi 5. The number of connected devices on the average WiFi network is expected to grow from roughly 10 now to 50 in a few years. The quality and volume of data consumed through WiFi networks are also both increasing. Faster WiFi for a faster world.

5. Blockchain Moves Beyond Crypto

Cloud computing is democratizing blockchain technology with its subscription-based blockchain-as-a-service platform. Examples beyond Crypto: food safety, intellectual property and royalties, and real estate/asset management.

6. 3D Printing

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes so that an object is created by laying down successive layers of material. Each of these layers can be seen as a thinly sliced cross-section of the object. 3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine. 3D printing uses less material than traditional manufacturing methods and can make parts available globally without the need for inventory. 3D printing will significantly reduce inventories since end products can be manufactured quickly virtually anywhere on the globe.

Why is the Fourth Industrial Revolution So Important?

Companies that transition to Industry 4.0/5.0 have many significant advantages.

Increased Competitiveness

For an industry that has relied heavily on low-wage regions for manufacturing cost reduction, investments in digital technology enable higher-wage countries to compete with offshore manufacturing hubs. This will let manufacturers select production locations according to technical capabilities and proximity to consumer demand, rather than decisions-driven primarily by wages.

Increased Productivity

With the increased use of AI in systems that can make autonomous decisions, output is projected to increase greatly.

Increased Revenue and Profitability

The implementation of Industry 4.0 will require heavy investment by manufacturers in the seamless integration of pre-production (i.e., engineering and design), production, and post-production (i.e., field performance and service). However, this transformation will offer new revenue opportunities. The closed-loop feedback created by Industry 4.0 data integration increases quality and reduces waste.

Optimized Manufacturing Processes

Machine-to-machine communications and integrated systems drive greater collaboration among producers, suppliers, and other stakeholders along the value chain.

Seamless Record-Keeping and Traceability

The automated closed-feedback loop is an inherent component of Industry 4.0. The seamless record-keeping enabled by digital systems will speed traceability, while limiting liabilities, warranty costs and recalls.

Minimized Supply Chain with Reduced Inventories

Since parts can be produced when and where they are needed, the supply chain is dramatically shortened and inventories can approach zero.

Achieving Successful Digital Transformation

Strategy is far more important than the individual technologies.

Technologies are only tools to get your company to its goal.

A cautionary note… These are only tools to be used with wisdom and care.

“If you already know how to solve a problem, AI can fundamentally transform the economics of your solution. But if you think our current algorithms can discover solutions you cannot, we have a serious problem.“

“Without the insight of human problem solvers driving our questions, “better numbers” mean nothing and our algorithms will never do more than reflect our own biases.

Neuroscientist Vivienne Ming in the “Financial Times”

Relax all of your existing assumptions.

A few of the critical questions to answer are:

- What are the major “pain points” for the customer in the existing ecosystem?

- How will the roles of the current actors change in the new ecosystem?

-

What role does your firm want to play?

Successful digital transformation requires thoughtfully addressing a wide range of such inquiries in the proper order.

My role is to guide you through this process and to oversee the execution.

Digital Transformation

High-Impact Results

+ Increased revenues

+ Increased margins and profits

+ Increased customer retention

+ Increased employee satisfaction

A new digital business model will improve your:

- Firm’s competitive position

- Capital efficiency, thereby reducing your need for capital

- Return on investment

- Terms to access capital: both financial and human

- Company’s valuation

Digital Transformation: Examples

Agricultural Production

Similar to what is happening with Smart Factories, Smart Farms pursue the interconnection of machines and systems with the premises, namely agricultural parcels and first-processing facilities. Efficiency of production systems—by means of optimization in the use of water, fertilizers and phytosanitary products—are originating what is denominated as Precision Agriculture. Two hundred (2%) British farmers use robots to milk cattle. The result is improved production and better hours.

Construction

Manufacturing Productivity

Manufacturing Productivity II

Personal Health

Preventative Maintenance

Replacement Parts

The pilot on a plane in flight learns that it needs a replacement part. Instead of being grounded for several days while waiting for that part to arrive, the part’s manufacturer sends the program to 3-D print that part to a 3-D print vendor over the internet who is at the plane’s destination. The part is printed and delivered to the airport before the plane lands. This strategy is used in other industries, as well.

Transform or Fail.

If you don’t get there first, your competition will.

Our Experience

Began working in the digital environment in the late Nineties with one of the first companies to use the cloud, where he was a member of the management team, and which was acquired by Oracle.

Established Comstock, combining artificial intelligence, wargaming and design thinking to develop a new business model for a digitally transformed world and continually updates it.

Senior Advisor to a CCaaS (“Contact Center as a Service) firm that was named the Best CCaaS Company in North America. That firm integrates artificial intelligence, the cloud, natural language processing to provide the leading contact center solution

Senior Advisor to a leading business process outsourcer for indirect purchasing.